GMP-compliant validation

Validation ensures and documents the most important properties of processes: Reproducibility and robustness. We take over the cleaning, process and transport validation as well as the computer and software validation for you.

The validation ensures in industries such as the pharmaceutical industry and the medical technology in addition to the risk based qualification your GxP standards. Testo Industrial Services supports you in individual validation projects or takes over the complete handling of your projects. Validation includes cleaning validation, transport validation, process validation or computer and software validation. For all validations, a risk-based approach is the basis of our tailormade services for you.

Validation secures processes

Validation is the process of demonstrating that your procedures, processes, equipment, materials and systems produce the expected and required results in accordance with the principles of Good Manufacturing Practice. We carry out the process validation for you in accordance with the EU GMP guidelines, Annex 15. For a computer/software validation (CSV), we follow the validation approach of the ISPE's GAMP 5 guide "A Risk Based Approach to Compliant GxP Computerised Systems".

Our service for you:

- Structure of the risk management and implementation of risk analyses

- Development of validation/qualification master plans

- Qualification support across all qualification phases - DQ, IQ, OQ and PQ

- Complete coordination of your project

- Individual measurements and calibrations

- SOPs and documentation creation

- Special services for companies from the Medical technology sector

- We share our practical expert knowledge and know-how with you

Transport validation

Proof of stable and verified climatic conditions in transport and logistics

Process validation

Creates reliable process results from planning to production

Computer and software validation

Process reliability for processes in which computer aided systems are integrated

Your advantage: Our competence

- Expertise: Consulting quality assurance, measurements, project management - our industry-experienced team supports you precisely & in line with your needs

- Technology: The use of our measuring equipment with more than 4,500 references ensures reliable measurement and test results

- Documentation: The documentation in the audit-proven layout or individually according to customer requirements will be handed over to you personally upon completion of the order

Risk management

In order to ensure the overall goal of patient safety, potential defects and hazards to product quality must be identified and brought under control. For this purpose, it is advisable to establish a comprehensive process of risk assessment, control and monitoring throughout the product life cycle.

We have been intensively involved in risk analysis and risk management for many years and know your requirements exactly. Our industry-experienced GxP Services team supports you in identifying weak points and risks with regard to product quality and patient safety, as well as in defining control measures and implementing them in the course of qualification and validation. Together we optimise your quality risk management.

This is how we support you in your quality risk management:

- Structuring and planning of compliance activities for sound risk management according to ICH Q9/EU-GMP Part III

- Integration of all project participants in the risk management process

- Structuring, preparation and moderation of risk analyses according to established methods (e.g. FMEA)

- Advice & support for the implementation of a risk management strategy

GxP services made to measure

More service, more security for your GxP compliance. Full service and know-how for your requirements.

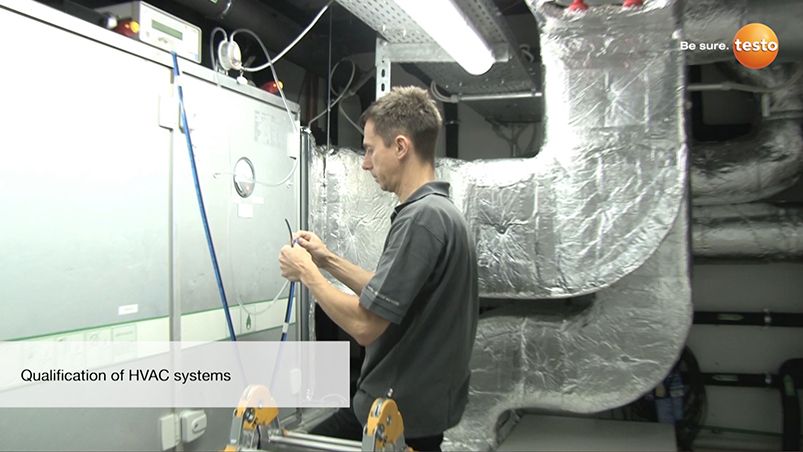

Opens video in overlayThe setting of Youtube cookies is blocked until an active click on the play button is made. With this click, you give your consent for Youtube to set cookies on the terminal device you are using. You can find more information on our data protection page.

Opens video in overlayThe setting of Youtube cookies is blocked until an active click on the play button is made. With this click, you give your consent for Youtube to set cookies on the terminal device you are using. You can find more information on our data protection page.Success stories

We support you in your projects and are committed to your goals. Here you will find an excerpt from the references of our successful GMP projects.

Grieshaber Logistics Group

GSP Compliance concept for a new logistics centre, GMP-compliant qualification and validation.

BBraun Medical AG Sempach

GMP upgrade of a production area including qualification, process and cleaning validation.

HEMA

Medical technology: Validation of an injection moulding process

Know-how

In our Knowledge-Centre you will find answers from our experts to numerous questions about validation. For example:

- What is a validation master plan?

- What is the goal of software validation?

- What are the core elements of the GAMP® 5 guidelines?

To read

Discover our comprehensive service portfolio. At Testo Industrial Services you receive all GxP relevant services from a single source.