Alongside validation, risk-based qualification is a central element of quality assurance in GxP-regulated industries, such as the pharmaceutical industry or medical technology. From the qualification of individual devices to the qualification and validation of complex plants, GMP upgrades or new construction projects in the compliance area, Testo Industrial Services offers you the necessary manpower, the know-how and the appropriate measurement technology individually and according to your needs.

Qualification - ensuring high quality in a GMP-compliant manner

Risk-based qualification is the documented proof that a facility/room is suitable for the intended purpose and complies with regulations and standards. Quality risk management (QRM) can be used to control and monitor all measures for controlling quality risks.

We would be happy to give you a detailed insight into risk-based qualification. Arrange an individual presentation appointment with our qualification experts today.

Our service for you:

- Support from individual measurements to project management

- Design and consulting quality assurance for risk-based planning and qualification of cleanrooms, plants and utilities, equipment as well as transport systems and storage areas

- Qualification support across all qualification phases - DQ, IQ, OQ and PQ

- Establishment of risk management and implementation of risk analyses

- Preparation of the qualification documents and reports

- Carrying out all qualification tests and measurements

- Complete coordination of your project

- Training your employees in practical seminars and workshops

- We share our practice-oriented expert knowledge and know-how with you

Cleanroom qualification

Safety and compliance for your cleanrooms

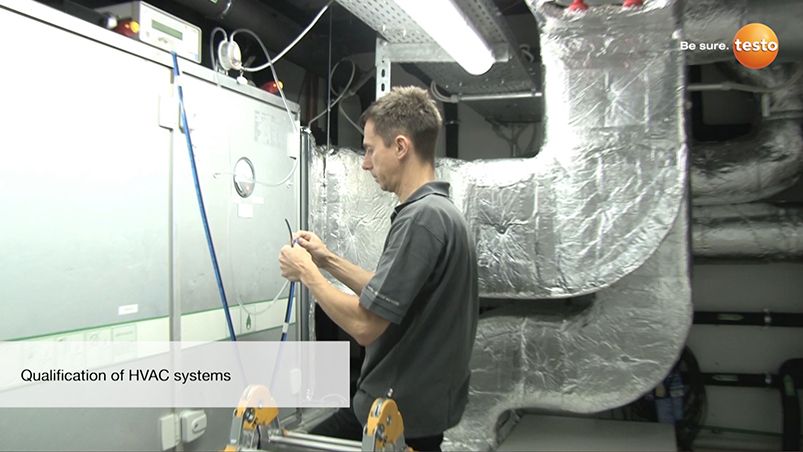

Qualification of plants & utilities

Ensures process stability and robustness

Transport and storage qualification

GxP services for storage areas, packaging and transport systems

Your advantage: Our competence

- Expertise: Consulting quality assurance, measurements, project management - our industry-experienced team supports you precisely & in line with your needs

- Technology: The use of our measuring equipment with more than 4,500 references ensures reliable measurement and test results.

- Documentation: We hand over the documentation in the audit-proven layout or individually according to customer requirements to you personally on completion of the order.

Risk management

In order to ensure the overall goal of patient safety, potential defects and hazards to product quality must be identified and brought under control. For this purpose, it is advisable to establish a comprehensive process of risk assessment, control and monitoring throughout the product life cycle.

We have been intensively involved in risk analysis and risk management for many years and know your requirements exactly. Our industry experienced GxP-Services Team supports you in identifying weak points and risks with regard to product quality and patient safety, as well as in defining control measures and implementing them in the course of qualification and validation. Together we optimise your quality risk management.

This is how we support you in your quality risk management:

- Structuring and planning of compliance activities for sound risk management according to ICH Q9/EU-GMP Part III

- Integration of all project participants in the risk management process

- Structuring, preparation and moderation of risk analyses according to established methods (e.g. FMEA)

- Advice & support for the implementation of a risk management strategy

Take advantage of the professional expertise of our engineers and technicians! Arrange a non-binding consultation appointment for your qualification project today:

GxP services made to measure

More service, more security for your GxP compliance. Full service and know-how for your requirements.

Opens video in overlayThe setting of Youtube cookies is blocked until an active click on the play button is made. With this click, you give your consent for Youtube to set cookies on the terminal device you are using. You can find more information on our data protection page.

Opens video in overlayThe setting of Youtube cookies is blocked until an active click on the play button is made. With this click, you give your consent for Youtube to set cookies on the terminal device you are using. You can find more information on our data protection page.Success stories

We support you in your projects and are committed to your goals. Here you will find an excerpt from the references of our successful GMP projects.

Losan Pharma GmbH

Full service support: cleanroom qualification and calibration

Paul Hartmann AG

New clean room construction: Project support & qualification

Grünenthal GmbH

Solids production: Qualification of a tablet line

Know-how

In our Knowledge-Centre you will find answers from our experts to numerous questions about qualification. For example:

- What is the difference between qualification and validation?

- What are the qualification phases?

- What are the objectives of quality risk management according to ICH Q9?

To read

Discover our comprehensive service portfolio. At Testo Industrial services you can obtain all GxP-relevant services from a single source.